Side Lock Bt40-sln End Mill Holder

New Products From This Supplier

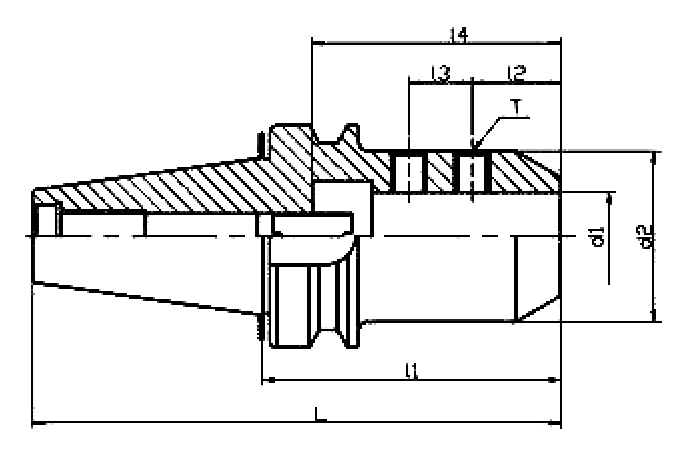

BT40-SLN16-75L Side lock end mill holder

BT SLN High Precision End Mill Holder, apply to the holder of a DIN1835-B with a solid surface of the cutting tool,

shank connection standard, mainly BT 30, BT 40, BT 50... Etc.. Mold industry, and high-speed engraving machine, used more.

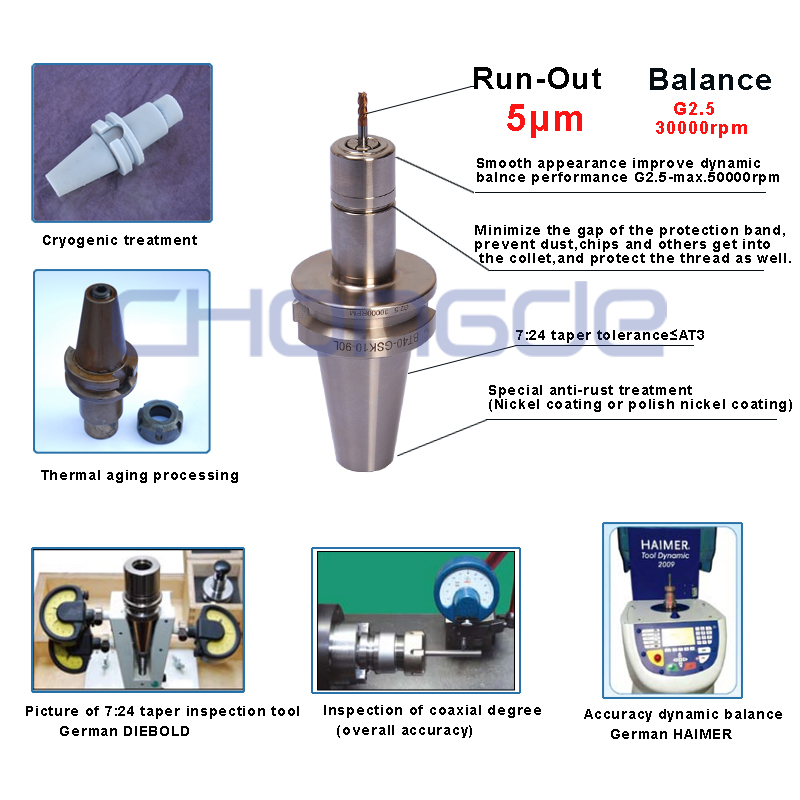

1. TIR: ≤0.0002"

2. Balanced to G 6.3 at 18,000 rpms

3. Works on all BT40 Machines

4. Rear thread for pull stud is M16*2.0P.

5. Constructed of alloy steel hardened to 56 – 60 HRC for long, durable service life

6. AT3 or better accuracy standard taper specification for maximum contact with spindle.

7. Nickel coating surface, Anti-rust, anti-corrosion, durability better.

Anti-rust, anti-corrosion, durability better.

◆Coating adhesion strong, enhance hardness, and anti-rust better in different surroundings, such as acid, alkali, ammonia, salt etc. Overall nickel coating, including inside and outside cone, even if you do not take any anti-rust actions, it will not rust either, don't influence processing precision and spindle . Improve cleanness, precision more stable, surface more smooth, feel more comfortable and appearance nicer.

◆Overall nickel coating, including inside and outside cone, even if you do not take any anti-rust actions, it will not rust either, don't influence processing precision and spindle.

*Cryogenic treatment

1.-196℃ long cryogenic, nearly all of the residual austenite into martensite;

2. Carbide precipitation of Nanoscale particles, increasing the hardness and toughness;

3. Reducing residual stresses;

4. Wear resistance significantly improved.

* Thermal aging processing long stereotyped thermal limitation removal of grinding residual stress.

Product Information

Technical Details Additional Information

| Brand Name | chongde | Size | BT40 |

| TIR | ≤ 0.0002" | Pilot Diameter(d1) | 12 |

| Drawbar Thread Size | M16*2.0P | Nose Diameter(d2) | 42 |

| Projection (l1) | 63 | Overall Length(L) | 128.4 |

chongde end mill tool holder side lock type tool holder BT30 End Mill Tool Holder

We are specialized in researching, producing and developing many kinds of collets, CNC Machine Tool Holder, ER nuts,ER spanners,machine vises,fasteners etc. With high quality and full varieties.

Surface roughness is reduced, precision stability improved.

The collet chuck surface uneven texture,after polishing,the surface roughness can be leveling ,smooth and shining surface.At the same time filling surface pores scratches and other surface defects,thus improve the fatigue strength,corrosion resistance increase.

Don't influence precision.

Chuck surface is coated ,the layer is evenly ,Chemical plating solution dispersion degree of almost 100%,nickel layer is thin ,thickness is about 3u-5u,this special coating can reduce Spindle abnormal wear and tear ,Don't influence precision.

Anti-rust,anti-corrosion,durability better.

Coating adhesiion strong,enhance hardness,and anti-rust better in different surroundings,such as acid,alkali,ammonia,salt etc.Overall nickel coating ,including inside and outside cone,even if you do not take any anti-rust actiions ,it will not rust either,don't influence processing precision and spindle .Improve cleanness,precision more stable,surface more smooth,feel more comfortable and appearance nicer.

Attaching importance to the reserch and products, we employs many experienced and skilled technicians,so that precision machining can be made according to samples or drawings.

Our factory

1.Package: plastic boxes and also can pack according to your requests.

2.Delivery time:Sample within 7 days and others 35 days.

I Fast reply

II Favourable price

III High quality products

IV Fast delivery

Ⅴ Good after-sales service

1.Are you factory or Trade Company?

We are industry and trade integration.

2.Could you supply samples?

Yes ,free samples for some products.

3.Where do you export?

The whole world.

4.Could you produce non-standard products?

Yes ,we can .Please supply samples or drawing.

5.What are the shipping ways?

By intemational express,by air ,by sea are all OK.

6.Do you have minimum order quantity?

Conventional Products don't have.The minimum order quantity of non-standard products is 50pcs.

7.What's your delivery time?

Less than 25 days after order confirmed .

Business Nature

Manufacturer

No. Employees

10

Country/Region

Jining, China

Main Products

Tool Holder, Collet Chuck, Er Collet, Sk Collet, Sk Collet, Er Collet, Collet Chuck, Tool Hold...

Shandong ChongDe Precision Machinery Co., Ltd is a new high-tech private enterprise and it is specialized in research and development, production and sales, producing high precision CNC machine tools and machine tool accessories. Shandong ChongDe has successfully developed collet chucks, CNC tools and other accessories with high accuracy, high precision and high speed, such as ER collets (5V, 8V), SK collets(5V), EOC(OZ) collets (10V), C-straight collets(10V) and BT/DIN69871(SK)CAT, HSK taper shank collet chucks, cutter head as well as other precision accessories, which are widely used in the machines with high balance and high accuracy.