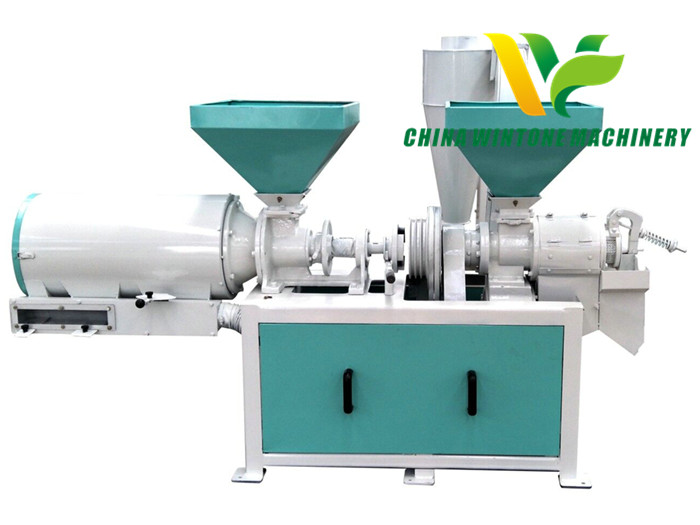

Ytzsf 28-5b Maize Peeling And Flour Milling Machine

New Products From This Supplier

Machine Introduction:

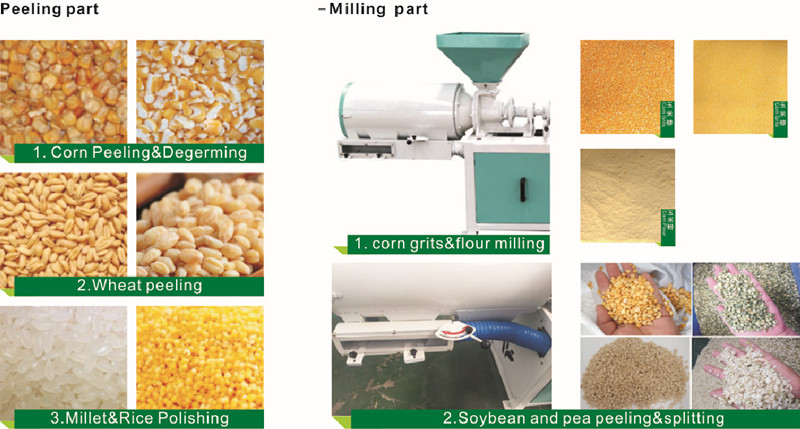

YTZSF28-5B Corn Peeling and Milling Machine is suitable for small size of food processing factories in corn hulling, grits and flour making, wheat hulling and millet polishing. It is the core equipment for a corn processing enterprise to produce corn grits and flour. This Corn Peeling & Milling Machine is our company's latest designed qualitative machine with extensive collection of users, and also replacement corn peeling milling machine on the market currently.

Working Principle of Corn Peeling and Milling Machine:

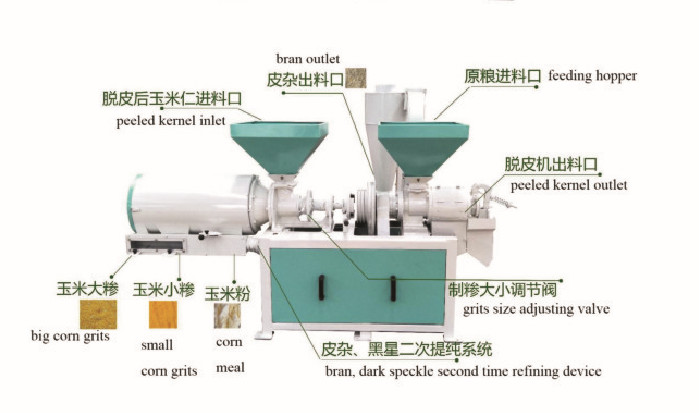

1. YTZSF28-5B Corn Peeling and Milling Machine consists of corn peeling, grits and flour milling, wheat hulling and millet polishing.

2. The clean raw grain is conveyed to the feeding inlet for peeling, degermination and black impurities removing and can be processed into corn kernels once.

3. After smashing and mixture grading, the machine can produce three end products: medium grits, small grits and corn flour. Inside of the machine, there is highly efficient air draft chamber for collecting the corn skin and further clean the micro powder and micro impurities in the corn grits.

Spare parts: grinding core, roller, peeling blade, peeling sieve, triangular belt, hairbrush.

Corn peeling and milling machine features:

1. This machine set adopts dry peeling technology. The products don’t touch water. Compared with wet peeling technology, this processing method is more sanitary.

2. This kind of machine is internally installed efficient winnowing and dust removal fan, which can remove and collect corn skin and the impurities and dust from grits processing, then eliminate and collect these skins and impurities by cyclone.

3. Low energy consumption, wide usage

4. The machine is unique and innovative, multi-functional, energy saving, low broken rate, high capacity, high yield.

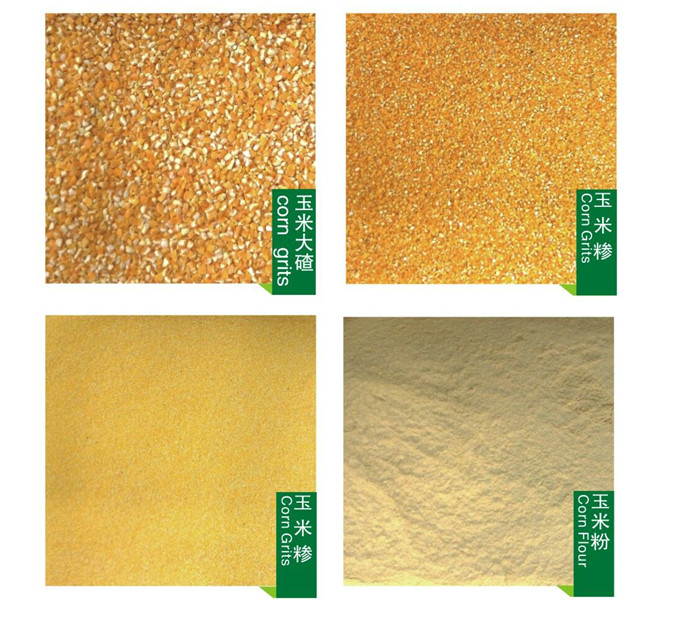

End Products :

YTZSF28-5B Corn Peeling & Milling Machine Technical Parameter:

|

Model |

Capacity |

Power |

Voltage |

Spindle Speed(r/min) |

Weight |

Size |

|||

|

(KG/H) |

KW |

(V) |

(KG) |

(mm) |

|||||

|

YTZSF 28-5B |

corn peeling |

corn grits |

corn flour |

wheat peeling |

11 |

380 |

1000-1200 |

350 |

2200x900x1200 |

|

500 |

1000 |

300 |

400 |

||||||

Business Nature

Manufacturer

Country/Region

Zhengzhou, China

Main Products

Millet /sorghum And Seeds Processing Machinery, Corn Processing Machinery, Beans Processing Equime...

Lushan Win Tone Engineering Technology Co., Ltd. was founded in 1995, which is an integration of high-tech machinery and equipment manufacturing enterprise. The company has complete sets of engineering design, research and development, manufacturing, sales and installation services. The company mainly produces the original, refined and deep processed food engineering equipment for corn, grains, food, health care, biological fermentation food. The products are applicable to production enterprises for all kinds of producing food, alcohol, starch, starch sugar. Located in the Industrial Cluster District in Lushan county, Henan Province. The company, with a total investment of 130 million yuan, covers an area of 60, 000 square meters. Among a staff of 280 people, 130 people have college degree or above, 53 people are the professional and technical, 21 people are process engineers. Therefore the company can customize the technical engineering solutions according to customer's requirements. The company was once only a coarse grain machinery manufacturing enterprises in Henan province at present. In August 2012, the company set up a complete set of technical research and development center and international trade and business center in the high and new technology development zone in Zhengzhou. The company has the ISO quality management system certification and 21 technical patents for new national practical products. Together with Zhengzhou Food Court, Henan University of Technology, etc. the company establishes technology research and development centre, which is appointed as the corn, grains research center of Henan province by the Chinese academy of sciences in 2013. The company introduced the spraying production line. It has more than 100 kinds of high-end machineries such as CNC machining center, laser cutting machine, CNC plasma flame cutting machine, CNC wedm, CNC lathe, CNC milling machine, CNC bending machine and so on. What’s more, the company has 4 series of packaged technology, totally 52 kinds, including complete sets of corn series and grains series, functional health food beverage process series, functional food complete biological fermentation process series and so on. The company sets up many business areas and 300 sales outlets both at home and abroad. The marketing network covers the whole country. The products sell well in more than 30 domestic provinces and even in more than 40 countries and regions, such as Latin America, Africa, Southeast Asia, which creates a record of 5 million dollars annual foreign exchange through export. Based on the concept of customers, considerate service, the company provides customers with quality services and opens 400 service hotline s, which help customers get derived profits. In accordance with the market concept of enterprise as the core, take the customer as the carrier, supported by science and technology, for the purpose of win-win, the company relies on the corn and grains research and development center in Henan province. With the current original, refined and deep corn and grains products, the company further researches the core processing products technology and keeps pace with international technology. Finally, we are confident to make more contributions to human health care! Our Mission: We work together to reduce grain loss, energy consumption, and labor costs for food and grain processing plants around the world. Our Vision: Help every client who uses our equipment to get more profits. Our Values: The business of the customer is our own business.